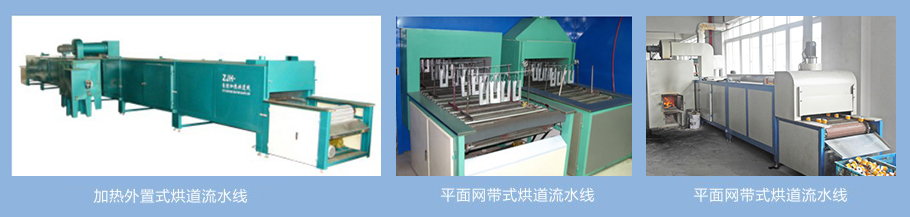

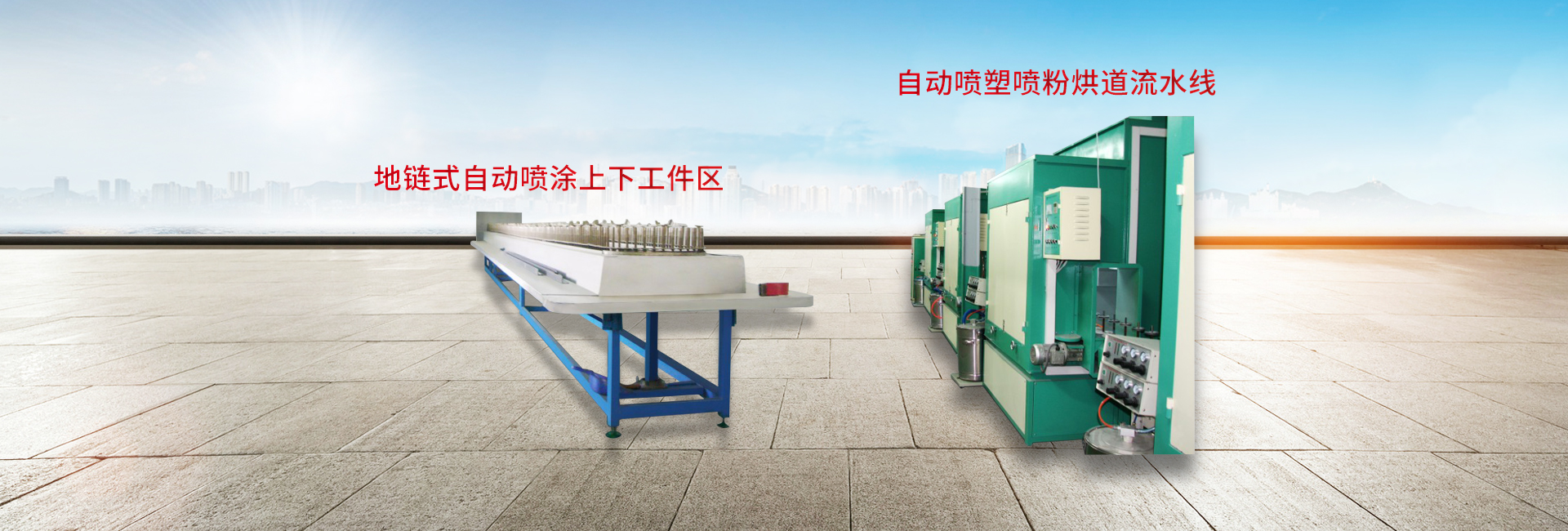

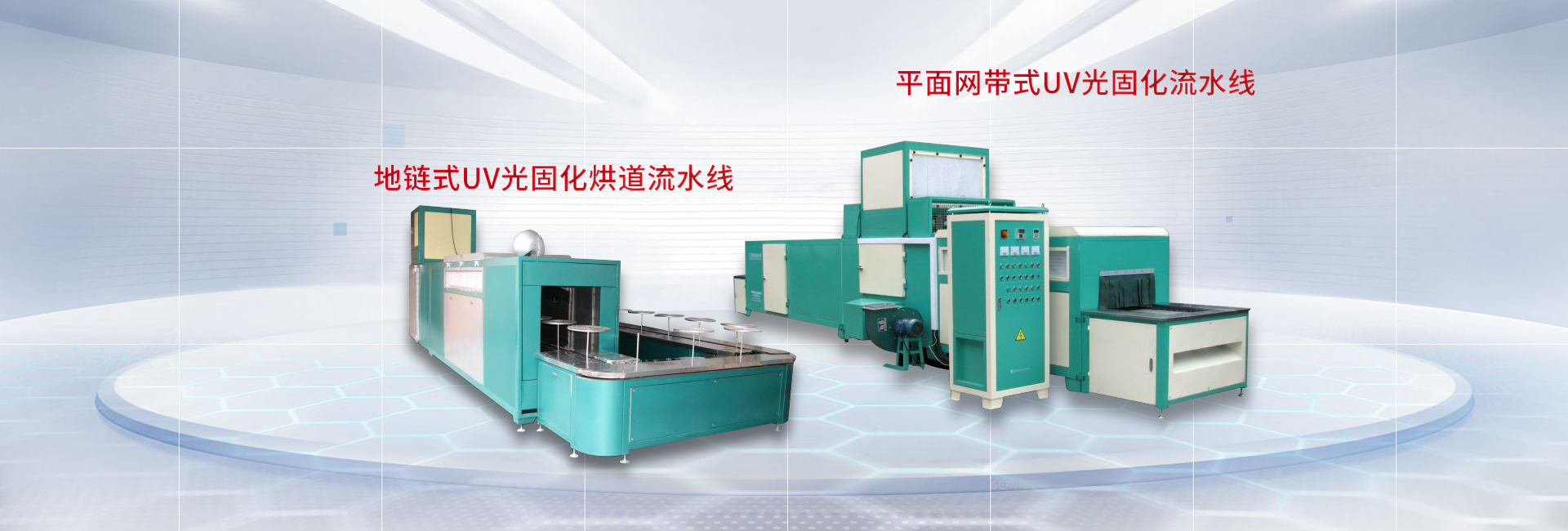

1、主要用於各行業產品的烘幹固化成型等。運行方式采用流水式,適合(hé)批量產品的生產,人工操作少的優點。

2、結構主要由烘幹箱體,輸(shū)送係統,加熱係統,控製係統,抽風係統等(děng)幾部分組成。

3、箱體框架結構,堅固結實,內置鍍鋅板或不鏽鋼板,外置冷軋鋼(gāng)板(bǎn),框(kuàng)架用2.0mm鋼板折彎(wān)焊接成型。

4、保溫層(céng)采用耐熱矽酸(suān)鋁岩棉,保溫效(xiào)果好。

5、輸送方式采用平麵網帶流水式,旁(páng)邊走滾輪鏈條,輸送平穩,順暢,速度可變頻調節。

6、加熱方式采用熱(rè)風吹入式、對流式(shì)、攪拌式、溫度均勻。能源用電,柴油,氣,煤,生物顆粒料等。

1、Products are mainly used in various industries such as drying curing. Run using water type, suitable for mass production. With high efficiency, less manual advantages.

2、Structure is dominated by drying cabinet, conveyor systems, heating systems,control systems, ventilation systems composed of several parts.

3、box frame structure, solid. The built-in galvanized sheet or stainless steel plate, external cold rolled steel, welding for 2.0mm steel sheet bent frame molding.

4、Insulation layer with high temperature silicate rock wool insulation effect.

5、Flat belt conveyor method using flow-through, walk beside roller chains, conveyor smooth, smooth,variable frequency speed regulation.

6、heating methods using hot air blowing type, convection type, mixing type, temperature uniformity. Energy, electricity, oil, gas, coal, biomass pellet etc.